Some Great Benefits Of Employing A Continuous Screw Press by Mingjia

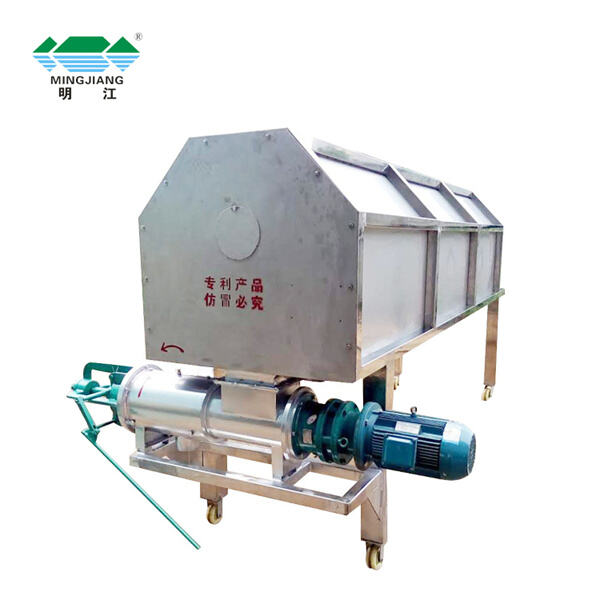

Would you like to extract oil from several types of seeds and nuts effectively and safely? After this you should think of employing a Continuous Screw Press if yes, along with Mingjia's product compost turner bin. This can be a number of equipment that utilizes screws which are heavy-duty press and extract oil from various materials such as cottonseed, soybean, and sunflower. We are going to talk about the advantages, innovation, security, use, how-to-use, service, quality, and application associated with the screw press constant.

The Continuous Screw Press has several advantages when compared to other types of machinery for oil extraction, the same as bone crushing machine built by Mingjia. One advantage significant it is high oil output, that could extract around 90% of oil from seeds and nuts. An benefit additional for an extended period without regular repairs that it is a diminished maintenance machine, which means you may use it. Also, a screw continuous is suitable for several kinds of materials, including soft to seeds that are hard.

Continuous Screw Press have undergone research development considerable improve their effectiveness, similar to the Mingjia's product like horse manure composting system. One innovation such the use of adjustable regularity drives to control the speed of the machine. This technology permits the consumer to modify the rate for the press to suit the variety and amount of oil extraction. Moreover, the employment of food-grade materials inside the production linked to the press means that it is safe and hygienic to utilize.

The Continuous Screw Press is made to guarantee maximum security for it is users, just like the industrial compost turner created by Mingjia. Common safety features consist of emergency stop buttons, protective covers, and security interlocks. A security is had by some models cage that prevents the consumer from being in touch with the moving aspects of the machine. Before utilizing the press, it is important to understand the safety features and instructions written by the maker.

Our manufacturing process among the most advanced market. We integrate cutting-edge advances guarantee high productivity and high quality product. We closely monitor each step of the manufacturing process, from the selection of raw materials delivery of final products, which guarantees the highest level of quality. Each part assured of their perfect quality. Our products are a mixture of quality and innovation created satisfy the wide array of continuous screw press, which a reflection of our commitment versatility and client satisfaction. We continually invest research and technology ensure that our manufacturing methods are the most efficient business. We are able keep our reputation as a quality-oriented firm.

With over 20 years dedicated research and experience continuous screw press reuse and processing, Mingjia stands as a beacon innovation and excellence. Our long-running journey has allowed us gain a wide range third party certifications that are a testament how we follow highest standards technology and sustainability. Our team industry experts and enthusiastic professionals not only skilled and knowledgeable, but they are also committed ethical and responsible service delivery. We have developed numerous methods and methods that are now industry standards, making sure our services not only meet but also exceed our clients' expectations in terms efficiency, compliance and environmental stewardship.

Our clients over 10 poland have praised our global reach and provided us positive feedback. This recognition from around the world is testament to our commitment to excellence all aspects of our business. We are extremely proud have several industry accolades and titles that highlight our leadership and contributions the waste sector. Collaborations with leading enterprises around the world have strengthened our standing market, but also enabled us encourage innovative thinking and raise standards for the industry. Our presence the waste treatment market is not just about business growth but about shaping a sustainable and environmentally-conscious future.

Mingjia's continuous screw press is based on the need provide quick, efficient, and client-focused service. Our staff is equipped with the expertise and the attitude quickly adapt and meet various demands of clients—our approach customer interaction and problem-solving bolsters our agility in service delivery. We're dedicate building relationships that go beyond transaction. By , we can provide an effortless, pleasant customer experience. We have built a reputation as dependable and trustworthy by our customers and partners by keeping a high degree of flexibility and responsiveness.

A Continuous Screw Press is straightforward to make use of, and also the procedure for oil extraction is straightforward, the same as Mingjia's industrial composting machine. First, you shall want to prepare the materials by cleansing it and having rid of any objects that could be international. Then, the merchandise is distributed by you into the press, and the screws will quickly compress it. The oil is extracted, additionally the remaining solid material is expelled through the discharge chute once the pressure increases. The oil extracted be collected in a receiver for space for storage or processing further.

To work with the Continuous Screw Press correctly, you need to adhere to the maker's directions, along with the manure composting system developed by Mingjia. Some steps which can be critical making sure the machine is neat and without having any debris or oil, checking the oil degree inside the gearbox, and adjusting the rate in line with the type or kind and degree of the materials being prepared. It is also advisable to monitor the warmth to make sure it does not surpass the recommended limit.

Continuous Screw Press need regular maintenance to make certain they operate at maximum effectiveness, just like the Mingjia's product called solid liquid separation filtration. Some upkeep vital include cleaning the feed ports and discharge chute, changing the oil in the gearbox, and replacing worn-out components. It is also wise to schedule inspections being routine identify any issues that are prospective rectify them before they escalate.

Copyright © 2023 Zhejiang Mingjia Environmental Protection Technology Co., Ltd