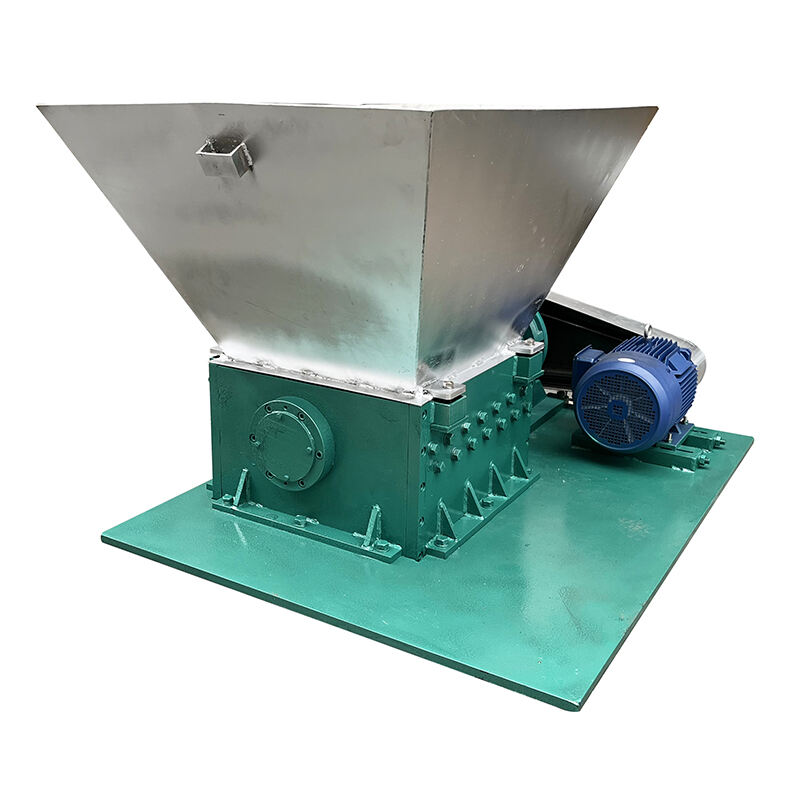

One of the most popular screw presses for Fasting Separation is a compact design that has made it more widely embraced in several industries. Slurry dewatering includes disposal of tonnes an hour, our machines offer low cost and durable sludge dewatering. They are easy to use, but a few approaches can make them more effective and improve how well they dewater.

When purchasing a compact screw press, the most important thing to consider is the size and motor specifications. Perfect Width, Length and Motor Horsepower The right width & length along with horsepower of the motor is needed to allow for peak performance. Also, cleaning and lubrication are some of the best maintenance tips. Maintaining your machine would prevent you from having to buy a new, more expensive one and make it last longer.

Processing the feed material correctly, is another important factor to improve dewatering performance. The feed material must be oversized and include a screen in order to prevent the machine from getting blocked going on to the inlet. In addition, any residual water must be eliminated before charging the machine with material. A consistent feed composition and viscosity helps to reduce variations in dewatering performance.

Several factors need to be considered in order for a compact screw press wastewater treatment package to work efficiently. This includes the operating parameters for which these machines are designed, including feed rate, screw speeds provided and solid retention time. Ultimately this leads to improved dewatering performance and increased throughput due the higher feed rates associated with optimizing screw speeds. Changing the machine's down angle of attack can also help optimize water elimination, affecting compression and material expulsion.

Compact screw presses are operated based on the principles of mechanical dewatering whereas pressure is applied to separate liquids and solids. The material is gradually pressed as the screw inside of the press pushes it into a chamber, and pressure increases until separation takes place. It uses a partial-cut technology which depends on such factors as material properties, press design and operational parameters. Compared inclined screw press dewatering better: tilted the body will make a longer dwell time in material squeezed more of this type band model estimated that compression forces increased.

The dewatering performance of compact screw press is affected by operation parameters i.e., feed rate, screw speed and solids retention time.DoesNotExist It is very important to optimize these parameters in order for the best results be obtained. Increasing feed rates will enable to increase throughput, may also influence on dewatering efficiency. Conversely, the lower feed rates improve dewatering efficiency to some extent at press throughput sacrificed. By changing the speed of the screws, throughput rates and dewatering capabilities can also be altered but with potential compromises.

In summary, the compact screw press is an inexpensive and efficient alternative for dewatering jobs. Control measurements must be taken to streamline their functionality nonetheless. Choosing the correct machine and achieving appropriate feed material preparation are critical to improving production efficiency and ultimately producing an effective dewatered end product.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

AF

AF

GA

GA

BE

BE

BN

BN

KM

KM

LO

LO

LA

LA

MN

MN

MY

MY

HAW

HAW