Types of Fermenters for Organic Fertilizer Production

Shopping for the fermenter which is appropriate their organic fertilizer production? There may vary kinds of fermenters accessible to suit different organic fertilizer procedures. We will speak about 5 different types of fermenters and their advantages, innovation, security, use, using, provider, quality and application.

1. Batch Type Fermenter

Batch type fermenter is many common type of used in organic fertilizer production. It is made for small-scale or medium-scale fertilizer is organic and it is operated manually. The Mingjia batch type fermenter comes in different sizes and forms and are made from steel as plastic.

The advantages of a batch type fermenter for organic fertilizer production are:

- The organic fertilizer machine production process is easy and easy to handle.

- It is economical as it will not need any sophisticated equipment.

- The organic fertilizer is of high quality.

- It could be utilized to make several types of organic fertilizer.

The innovation in batch type fermenters is the application of computerized controls that produce the production process considerably efficient. The use of sensors and pc software the fermentation process guarantees which the organic fertilizer is top quality.

To employ a batch type fermenter for organic fertilizer production, you need to:

- Prepare the organic waste that'll be utilized for fermentation.

- Load the organic materials the fermenter.

- incorporate water and other formulation which can be necessary.

- Monitor the fermentation procedure and adjust the circumstances as needed.

- following the fermentation is complete, you can remove and bundle the organic fertilizer.

2. Continuous Type Fermenter

Continuous type fermenter is designed for large-scale fertilizer organic production. It operates continuously and immediately, and it is made of stainless steel. The continuous type is prepared with advanced fertilizer making machine techniques which facilitate the fermentation procedure, such as aeration, agitation and temperature control.

The advantages of this continuous type for organic fertilizer production is:

- it may build big levels of organic fertilizer in a short celebration.

- The production process is automated, which decreases work costs.

- the organic fertilizer is of great quality.

- it might be utilized for long-lasting fertilizer organic production.

The innovation in continuous type fermenters is the employment of advanced sensors and computer software which control and monitor the fermentation procedure. This guarantees that the organic fertilizer satisfies the mandatory standards.

To work well with the continuous type for organic fertilizer production, you will want to:

- Load the organic waste products in to the feeding system.

- the feeding machine automatically move the organic material to the fermenter.

- Add liquid and other ingredients which are essential.

- The fermenter can automatically control the temperature, aeration and agitation procedures.

- after the fermentation is complete, the organic fertilizer be automatically released.

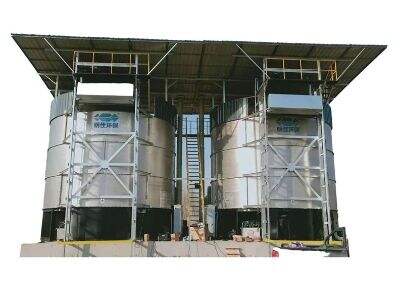

3. Tower Type Fermenter

Tower type fermenter is a vertical fermenter for high-density waste organic products. It is made of stainless steel and might be ideal for large-scale fertilizer organic production. The tower type fermenter is constructed with advanced level techniques which optimize the fermentation process, such as aeration, agitation and temperature control.

The advantages associated with the tower type fermenter for organic fertilizer production is:

- It was created for high-density waste organic product.

- The production process is efficient, that reduces production time and work costs.

- the organic fertilizer is of top quality.

- it can be utilized for long-term fertilizer organic fertilizer equipment production.

The innovation in tower type fermenters is the use of higher rate sensors and software that control and monitor the fermentation process. This can help to ensure that the organic fertilizer meets the requirements that are mandatory.

To use a tower type fermenter for organic fertilizer production, you will have to:

- Load the organic waste to the feeding system.

- the feeding unit transfer the organic materials near the top of this fermenter.

- Add water and other stuff that are essential the most notable for the fermenter.

- The fermenter can automatically control the temperature, aeration and agitation processes.

- After the fermentation is complete, the organic fertilizer be immediately discharged from the root of the fermenter.

4. In-vessel Type Fermenter

In-vessel type fermenter is a container made for enclosed spend material organic fermentation. It is manufactured from stainless steel or reinforced concrete. The in-vessel type is constructed with high level systems which optimize the fermentation process, such as temperature control and air circulation.

The advantages of an in-vessel type for organic fertilizer production are:

- it might manage enclosed organic waste.

- The production procedure is efficient, that decreases production time and work expenses.

- the organic fertilizer is of great quality.

- it may be utilized for long-lasting fertilizer organic production.

The innovation in in-vessel type fermenters is the use of advanced sensors and software which control and monitor the fermentation procedure. This helps to make sure that the organic fertilizer meets the standards that are needed.

To use an in-vessel type for organic fertilizer production, you'll want to:

- Load the enclosed waste is organic in to the in-vessel.

- incorporate liquid and more components which are often necessary.

- The fermenter can immediately control the temperature and atmosphere blood supply.

- following the fermentation is complete, the organic fertilizer be automatically released through the in-vessel.

5. Horizontal Fermenter

Horizontal fermenter is the container made for large-scale waste material organic fermentation. It is produced from stainless steel and is built with advanced techniques which optimize the fermentation process, such as temperature control and atmosphere the circulation of blood.

The advantages regarding the horizontal type for organic fertilizer production is:

- it may manage big amounts of organic waste.

- The production procedure is efficient, that decrease production time and labor expenses.

- the organic fertilizer is of good quality.

- it could be used by long-term fertilizer organic production.

The innovation in horizontal fermenters is use of higher level sensors and software that control and monitor the fermentation procedure. This means that the organic fertilizer meets the mandatory standards.

To use a horizontal type for organic fertilizer production, you will need to:

- Load the organic spend material into the feeding system.

- the feeding machine immediately move the organic material the fermenter.

- Add liquid and more necessary things.

- The fermenter can immediately control the temperature and atmosphere circulation.

- after the fermentation is complete, the organic fertilizer be immediately released.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

AF

AF

GA

GA

BE

BE

BN

BN

KM

KM

LO

LO

LA

LA

MN

MN

MY

MY

HAW

HAW