Ever wondered how drinks like beer, and wine are made? It’s a fascinating process! Fermentation is a unique process that converts sugar into alcohol. That, my friends, is how many of our best-loved beverages are made. Fermentation was traditionally carried out in open barrels, which thought not only endlessly slow but also needed tireless nervous.

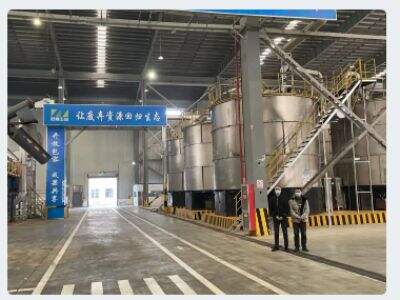

But now theres a new one method called tank fermentation and it goes faster. In tank fermentation, the enclosed container can be precisely controlled. It regulates the temperature and moisture is also important that sugar easily transforms to alcohol. Now, the complete fermentation process takes less time and also enhances your preparation. Mingjia will help you here.

Keeping Track of Conditions

To perform well in tank fermentation and Drying equipment, maintaining suitable conditions inside the Fermentation Unit is key. The container MUST provide the appropriate temperature, humidity and oxygen levels. All of these things assist the yeast in doing its job efficiently which is key for fermentation to work.

These levels are monitored continuously by various systems located within the tank. When something is wrong, the system will correct it itself without any human intervention. This is why the fermentation process will go easy for you and be perfect as good one. Watching these variables carefully is what makes for successful tank fermenting!

More Alcohol from Less Sugar

The fact that tank fermentation can yield higher alcohol levels is another advantage. The yeast works more efficiently as the container is completely sealed and governed closely. It helps result into fermentation better.

More sugar turning into alcohol, more drinks for our efforts! This is particularly advantageous for companies who can then produce more materials without the need to find extra resources. Makers of drinks, therefore, have always an interest in maximizing productivity and this is especially true when more alcohol can be obtained with less sugar.

Cheaper Production

Tank fermentation can also be very cost effective when you compare with the traditional methods of wine processing. As it is, this speeds up the process and lowers Fermentation vessel overall cost since you use less time/energy to create X number of drinks. This allows manufacturers to cut down on costs — a lot is riding and their business lives or dies here.

Furthermore, the enclosed container keeps better control of how your ferments are going on. That minimizes the risk of spoilage, or of someone getting sick—which is incredibly expensive. For breeds with short coats, general sanitary maintenance can be done at home right before grooming visits to reduce the wasted product and thus money lost in a win-win for both!

Consistent Quality

Lastly, one of the great parts about tank fermentation and Crushing equipment is that it consistently crafts high quality. Traditional fermentation techniques may be less consistent as they depend on natural variables like climate and temperature that can vary significantly.

However, when the fermentation occurs in tanks nothing is left to chance and this way all quality standards can be easily maintained. Manufacturers in particular, do not like surprises with their supply chain consistency. They can be sure every drink will taste good!

All in, tank fermentation is a pretty brave new notion of the drinking world. Manufacturers And For Consumers Are Also Offered Through Faster, Better As Well As More Consistent This should give you a bit of insight into the wonderful journey that beverage took to quench your thirst. With the beverage industry in general currently bustling with new ideas, tank fermentation lossy plays into cordials current palette of change.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

AF

AF

GA

GA

BE

BE

BN

BN

KM

KM

LO

LO

LA

LA

MN

MN

MY

MY

HAW

HAW